Introduction:

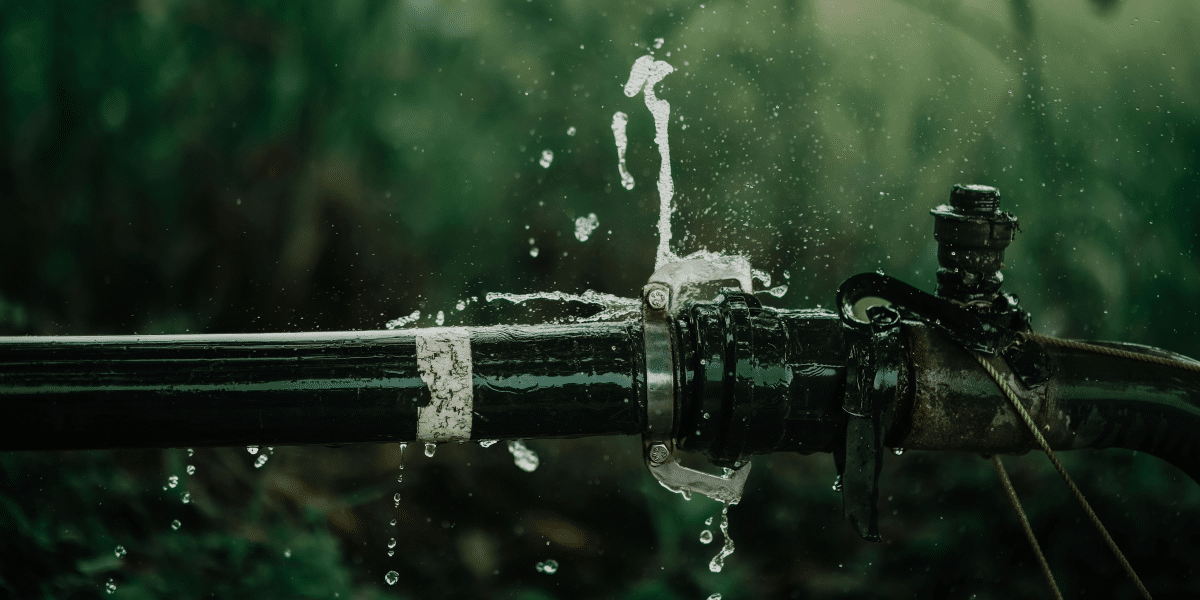

Leakage Tube are basic parts in different modern, auto, and homegrown frameworks, yet they frequently slip by everyone’s notice until an issue emerges. From guaranteeing the legitimate working of machines to keeping up with well-being in liquid frameworks, Leakage Tube assume a fundamental part in current design and ordinary applications.

This article investigates the reason, types, uses, and upkeep of Leakage Tube, giving you a far-reaching comprehension of its significance.

What is a Spillage Cylinder?

A spillage tube is a specific conductor or line intended to oversee or identify spills in frameworks that transport liquids, gases, or different substances. These cylinders are either purposefully coordinated into frameworks as a feature of break recognition instruments or designed to deal with potential holes securely without making harm-encompassing parts.

Uses of Spillage Cylinders

Leakage Tube are utilized across different businesses because of their flexibility and basic usefulness. Key applications include:

1. Modern Frameworks

In assembling plants, Leakage Tube are integrated into water-driven and pneumatic frameworks to screen and control liquid holes, guaranteeing continuous activities and limiting perils.

2. Car Area

Vehicles depend on Leakage Tube in slowing mechanisms, cooling circuits, and fuel lines to recognize and divert spills, keeping up with well-being and execution.

3. Plumbing and central air Frameworks

Leakage Tube are normal in private and business plumbing frameworks to forestall water harm and recognize spills in central air units.

4. Oil and Gas Industry

In high-pressure conditions like pipelines and processing plants, Leakage Tube assists with overseeing unintentional spills and holes, guaranteeing well-being and administrative consistency.

Sorts of Spillage Cylinders

Leakage Tube comes in various materials and plans, contingent upon the application:

1. Adaptable Spillage Cylinders

Produced using materials like elastic or silicone, these cylinders are often utilized in unique frameworks that require flexibility and protection from vibration.

2. Inflexible Spillage Cylinders

Developed from metals like treated steel or aluminum, unbending Leakage Tube are great for high-strain and temperature frameworks because of their strength.

3. Straightforward Cylinders

Frequently utilized for release identification, straightforward cylinders permit administrators to investigate for the presence of liquids or gases outwardly.

4. Diverse Cylinders

These cylinders highlight various layers of materials, like polymers and metal fortifications, offering upgraded spill opposition and life span.

Advantages of Spillage Cylinders

Leakage Tube give various advantages, including:

Spill Location: Early recognizable proof of holes forestalls expensive fixes and margin time.

Security Upgrade: Diverting releases from basic regions limits dangers to staff and gear.

Framework Life span: Controlling holes decreases mileage on framework parts.

Natural Security: In enterprises like oil and gas, overseeing spills forestalls defilement and follows ecological guidelines.

Instructions to Keep up with Spillage Cylinders

1. Customary Investigations

Check Leakage Tube occasionally for indications of wear, breaks, or consumption. Early location can forestall framework disappointments.

2. Legitimate Establishment

GuaranteeLeakage Tube are introduced safely and adjusted accurately to stay away from superfluous pressure or wrinkles.

3. Utilize Viable Materials

Pick Leakage Tube produced using materials reasonable for the framework’s strain, temperature, and synthetic openness.

4. Supplant Harmed Cylinders

Continuously supplant Leakage Tube giving indications of harm to keep up with framework proficiency and security.

FAQs

1. What are Leakage Tube utilized for?

Leakage Tube are utilized to recognize, make due, or divert spills in frameworks that transport liquids or gases, guaranteeing security and functional proficiency.

2. Will the Leakage Tube forestall all breaks?

While spillage cylinders can oversee and identify spills successfully, they are not a substitute for legitimate framework upkeep and review.

3. How frequently should Leakage Tube be assessed?

Reviews ought to be led no less than one time each year or as suggested by the producer, particularly in high-strain or high-temperature frameworks.

4. What materials are best for Leakage Tubes?

The best material relies upon the application. For high-pressure frameworks, tempered steel is great, while elastic or silicone functions admirably in adaptable and low-pressure conditions.

5. Are Leakage Tubes harmless to the ecosystem?

Indeed, they assist with limiting natural harm by securely overseeing spills in enterprises inclined to unplanned liquid or gas spills.

End

Leakage Tube are imperative parts in guaranteeing the security, proficiency, and dependability of different frameworks. Whether utilized in modern applications, auto frameworks, or family plumbing, their part in overseeing spills can’t be put into words. Standard support and appropriate choice of materials can improve their adequacy, making them a fundamental speculation for any activity.

Explore More: proasurascans